Polyester fibers are some of the most commonly used fibers. This is mainly due to their excellent price-performance ratio. The fibers are produced using the melt spinning or polycondensation process and are extremely versatile:

Some examples of the use of short-cut polyester fibers would be in the field of NVH (noise, vibration, harshness) as a nonwoven fabric, e.g., for interior insulation, as a reinforcing fiber for thermoplastic compounds, e.g., a polypropylene matrix, or in filtration technology.

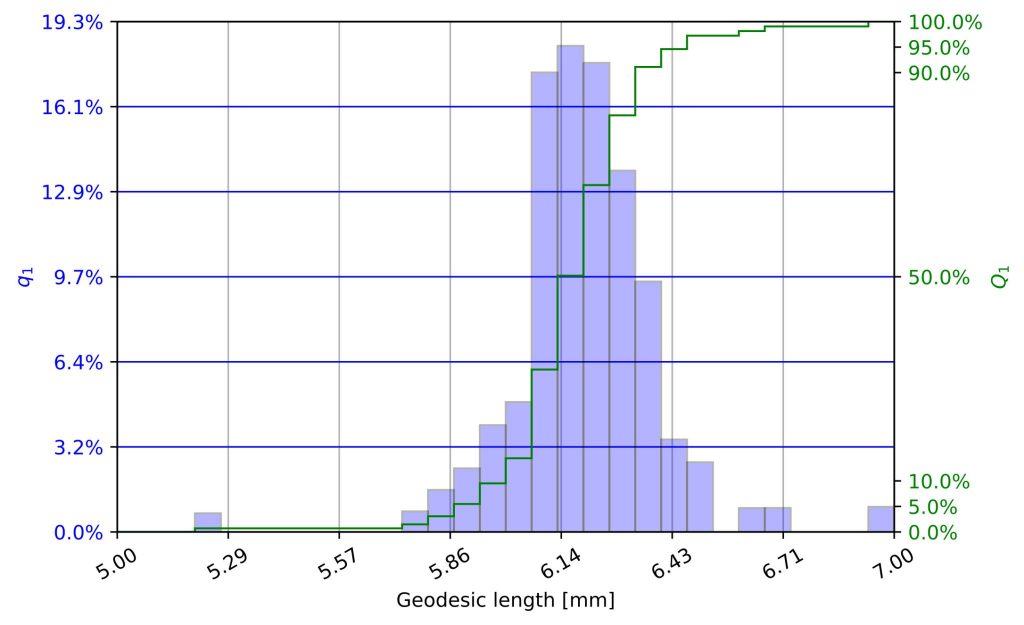

The example shown is 6 mm short-cut fiber. In this application example, it is important that the fibers have a homogeneous length. FibreShape can be used to monitor compliance with the quality requirements of the cut material. Changes in the statistical distribution allow conclusions to be drawn about the condition of the cutting tool.

A special feature of polyester fibers in terms of measurement technology is their transparent properties. This causes the fibers to fade under certain lighting angles when line lighting is used. Measurement inaccuracies can be avoided here by using an angle filter.

In the case of short-cut fibers, a fiber bundle is usually cut in the form of a roving. Accordingly, all fibers in this cut bundle are approximately the same length. It is therefore important to measure fibers from as many different bundles as possible. Otherwise, significant statistical shifts may occur.