Polyamides are technical fibers produced by polycondensation of diamines with dicarboxylic acids (PA6.6) or by ring-opening polymerization of lactams (PA6).

But how do the two polyamides differ?

PA6: produced from ε-caprolactam (ring opening), linear chain structure with repeating amide group every 6 atoms → cheaper, tougher, but higher water absorption, lower heat resistance.

PA6.6: produced from hexamethylenediamine + adipic acid (step growth reaction), denser molecular structure → higher crystallinity, strength, abrasion and heat resistance, slightly more brittle, more expensive than PA6.

PA6.6 fibers, but mostly PA6 fibers, are mixed with recycled carbon fibers (rCF) during carding to produce homogeneous nonwovens. During carding, it is crucial that both fiber types are matched in terms of fiber length and fineness in order to achieve a uniform mixing ratio and thus reproducible mechanical properties.

The finished nonwoven fabric can then be bonded and thermally consolidated into a sheet, or stretched for tape production and then thermally consolidated.

In addition to its role as a matrix, PA6.6 can also be used as a reinforcing fiber itself, e.g., in thermoplastic compounds. Its high abrasion resistance, strength, and temperature stability make it interesting when a certain degree of toughness is required in addition to stiffness.

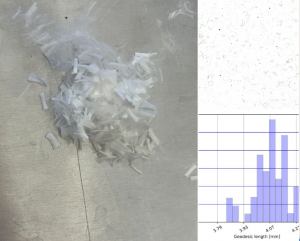

The fibers shown are 4 mm long. 6 mm or 12 mm are also common and depend on the application. Longer fibers generally offer better properties, but are usually also more difficult to process.

FibreShape can be used to monitor compliance with the length distribution. This is particularly important for short-cut fibers in order to ensure homogeneous mixing and consistent properties in fleeces and compounds.

As with other short-cut fibers, a fiber bundle is usually cut in the form of a roving. Accordingly, all fibers in this cut bundle are approximately the same length. It is therefore important to measure fibers from as many different bundles as possible. Otherwise, significant statistical shifts may occur.

As with other synthetic, transparent, or semi-transparent fibers, PA6.6 also exhibits bleaching effects under line illumination. These can be significantly excluded from the measurement by using an angle filter.