The processing of hemp is becoming increasingly important in Europe. Partly to compensate for climate-related losses in European flax production.

What are hemp shives?

Hemp shives are the woody, inner parts of the hemp stalk that remain after the bast fibers have been removed. They are light, absorbent, and naturally mold-resistant.

As a by-product, shives offer exciting applications, especially in hemp lime (hemp-lime building material).

The light hemp plant with its open cells:

- absorbs air, water, or moisture

- thereby improving thermal insulation and heat buffering

In the long term, the lime reacts with CO₂ from the air (carbonation) and coats the shives with a mineral layer. This reliably protects them from mold, insects, and rot – even in humid climates.

The wide variation in the size of the shives poses particular challenges:

Coarse material is initially scanned at a high resolution (800 ppi) in order to capture even fine particles.

The resolution is then gradually reduced in order to hide details such as fine fibers and measure only the “stem” of the shive.

In the accepted-rejected (Figure 3), you can see that some shives are measured at approx. 300 ppi, while coarser material is only detected at 100 ppi. The FibreShape from IST – Innovative Scan Technologies GmbH adjusts these steps fully automatically.

When taking samples, care must be taken to ensure that the entire material mixture is recorded representatively. Since coarse shives often settle at the top and fine particles or dust at the bottom of the bag, stratification can occur, which distorts the result.

Weighting method

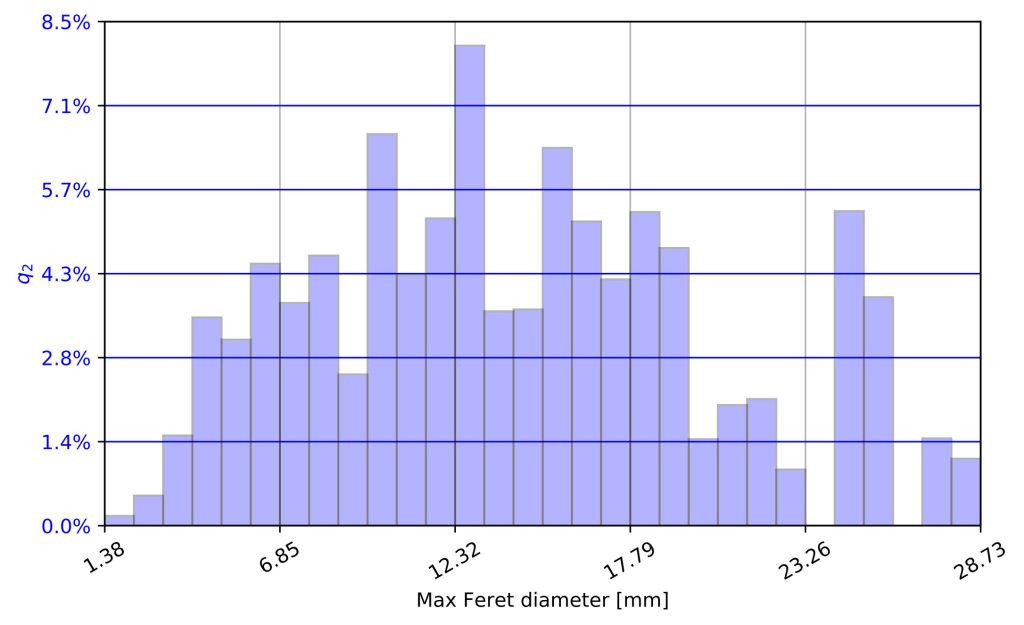

Due to the variation in length and width, a surface weighting (q₂) is used.

This ensures that each part is represented in the correct proportion to the total volume of the sample.

For synthetic fibers or very uniform natural fibers, on the other hand, a length weighting (q₁) is often useful.

Our expertise in measuring hemp shives is not only used for material characterization for customers. We also contribute our know-how to standardization committees such as ASTM in order to advance the industry as a whole through the standards developed there.