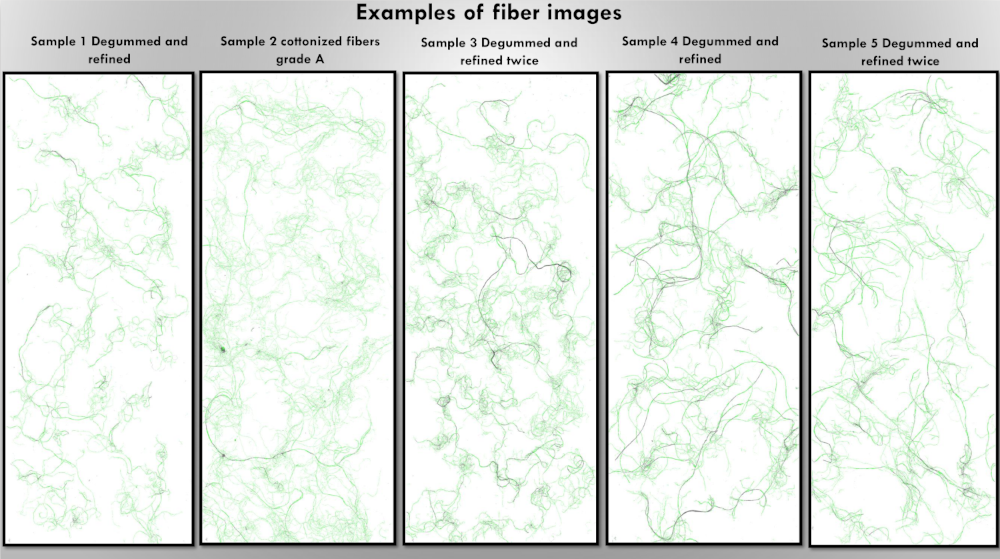

Industrial hemp fibers have a wide range of uses including geotextiles, composite material, construction material, non-woven and textiles. The application of hemp fibers depends on the type of hemp fibers and the way they are processed and refined.

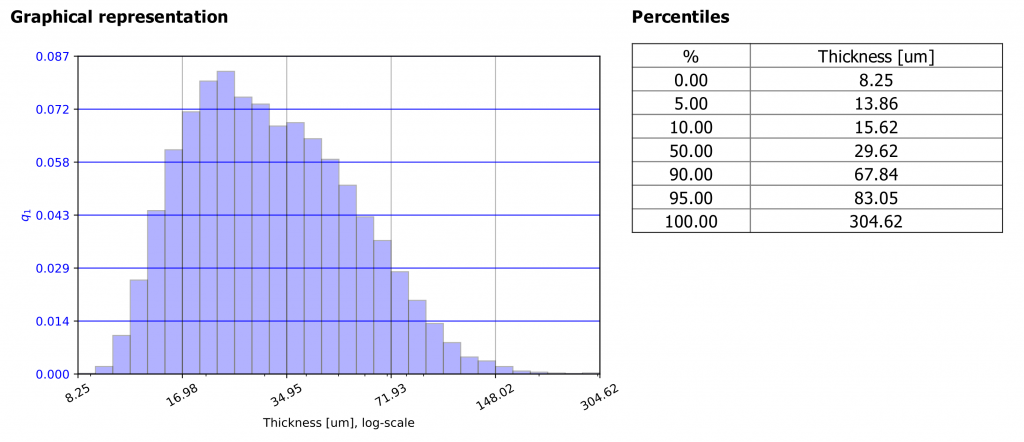

The FibreShape system and its length and width analysis allows to classify the thickness of all type of industiral hemp fibers and to compare hemp fibers of different qualities – deriving from different providers or resulting from different process steps. With the FibreShape system a direct comparison of the tickness of fibre a,b,c and d is possible. A long-term comparison is possible when building up a database.

Hemp is retted in the field to remove the fibre from the stem. The fibres are then further processed in different processes as decortication, refining and degumming.

Typical processing steps decortication processes (hammermilling, scutching, breaker), refining (carded, combed), degumming and cottonizing.

Hemp fibers have many environmental benefits. They require less water and pesticides than other crops, are naturally resistant to insects, allows multiple harvesting per year and don’t need any fertilizer. ´

Distribution of thickness analysis:

How to characterize hemp shives or hurds? Have a look at the article of Philipp Huber about characterising hemp hurd!